© paulrommer - fotolia

Many years of research and development and decades of experience using reactive PUR hotmelt systems provided the basis and conditions for the successful market launch of KLEIBERIT’s HotCoating® technology. It intelligently combines PUR technology with UV varnishing technology in a unique way. Today, more than 50 systems are installed across the world for finishing and coating furniture elements, floors, facades, and rolled goods for profile wrapping.

HotCoating surfaces have exceptional properties and have been tested and certified according to the latest relevant international standards. Workpieces and meter goods up to widths of 2400mm can be coated in the surprisingly easy-to-use HotCoating process.

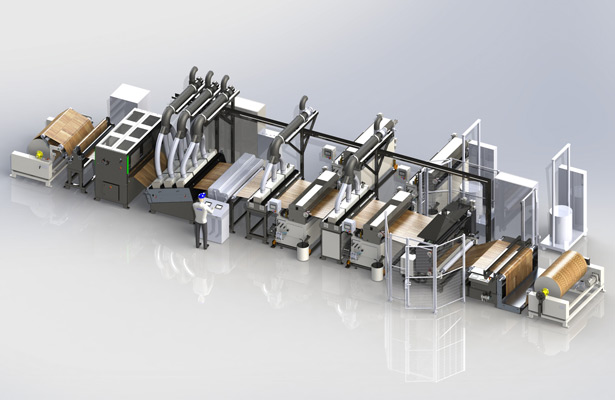

© Huser Maschinenbau GmbH

KLEIBERIT HotCoating® is an innovative surface technology that involves applying a hot reactive PUR mass rather than a classic varnish.The method and the respective materials were developed and patented by KLEIBERIT. HotCoating is melted in a pre-melting unit and then applied with a heated roller system using reversing rollers or roller bar nozzles. A liquid varnish – usually a UV-curing, acryl-functional varnish – is then applied on top, typically with a roller system, to serve as either a base or top coat. The innovative features and benefits of this surface coating technology lie in the processing method as well as in the exceptional properties,

such as:

- very easy processing in a single run

- low investment costs / very low space requirements

- no energy needed for the curing phase (moisture-induced cross-linking)

- variable quantities can be applied with a single application roller: 15-150 g/m²

- easy cleaning

- technology innovation, but less complex and interlinked:

fewer work steps, fewer potential error sources, flexible availability.

Micro-emission

KLEIBERIT HotCoating®is a 100% solid-state system without any VOC or formaldehyde emissions. The reactive PUR KLEIBERIT HotCoating® system has an extremely low residual isocyanate content of less than 0.1%, which reduces possible monomer emissions to an absolute minimum. HotCoating is generally classified as “ME” (micro-emission). It is therefore exempt from hazard labeling, and customers are not required to give their staff a special training.

Renewable raw materials

At KLEIBERIT we are firmly committed to continuously introducing more renewable raw materials. Our PUR hotmelts were engineered with bio-based raw materials and can be used for many purposes, such as edge banding and profile wrapping in the textile industry, etc. The KLEIBERIT HotCoating® system already contains bio-based raw materials.Products finished with KLEIBERIT HotCoating® can be offered as ‘bio-based’ containing more than 50% renewable raw materials. Bio-based alternatives for UV-curing acrylic varnishes are also in the pipeline.